The restoration team made exceptional progress returning Kanana back to its former glory throughout the month of November.

Looking ahead, the team is gearing up to deliver the final touches over the coming months.

Some of November’s greatest achievements include:

1. Elevators, Rudder & Ailerons installed and rigged

At the back of the aircraft, the rudder and elevators have been installed and rigged to their proper positions. The ailerons have been installed on the wings.

The rudder on the aircraft acts in a similar manner to the rudder on a boat. It controls the yaw (movement about the vertical axis) of the aircraft, and its purpose is primarily to help keep the aircraft balanced in flight.

The elevators control the pitch of the aircraft when moved by the pilots’ control column, raising and lowering the tail of the aircraft. With the rudder and elevators rigged, the tail assembly of the aircraft (also known as the empennage) is all set and ready. The empennage is vital to maintaining the stability of the aircraft during flight.

The ailerons control roll and are used to turn the aircraft. Attached along the outer trailing edge of each wing, they are moved by the pilots’ control wheel.

This is the same function as displayed on modern airliners. A DC3 will maintain a cruise speed of approximately 130 knots depending on prevailing winds at the time, much slower than a modern aircraft of today traveling at speeds up to 300 knots.

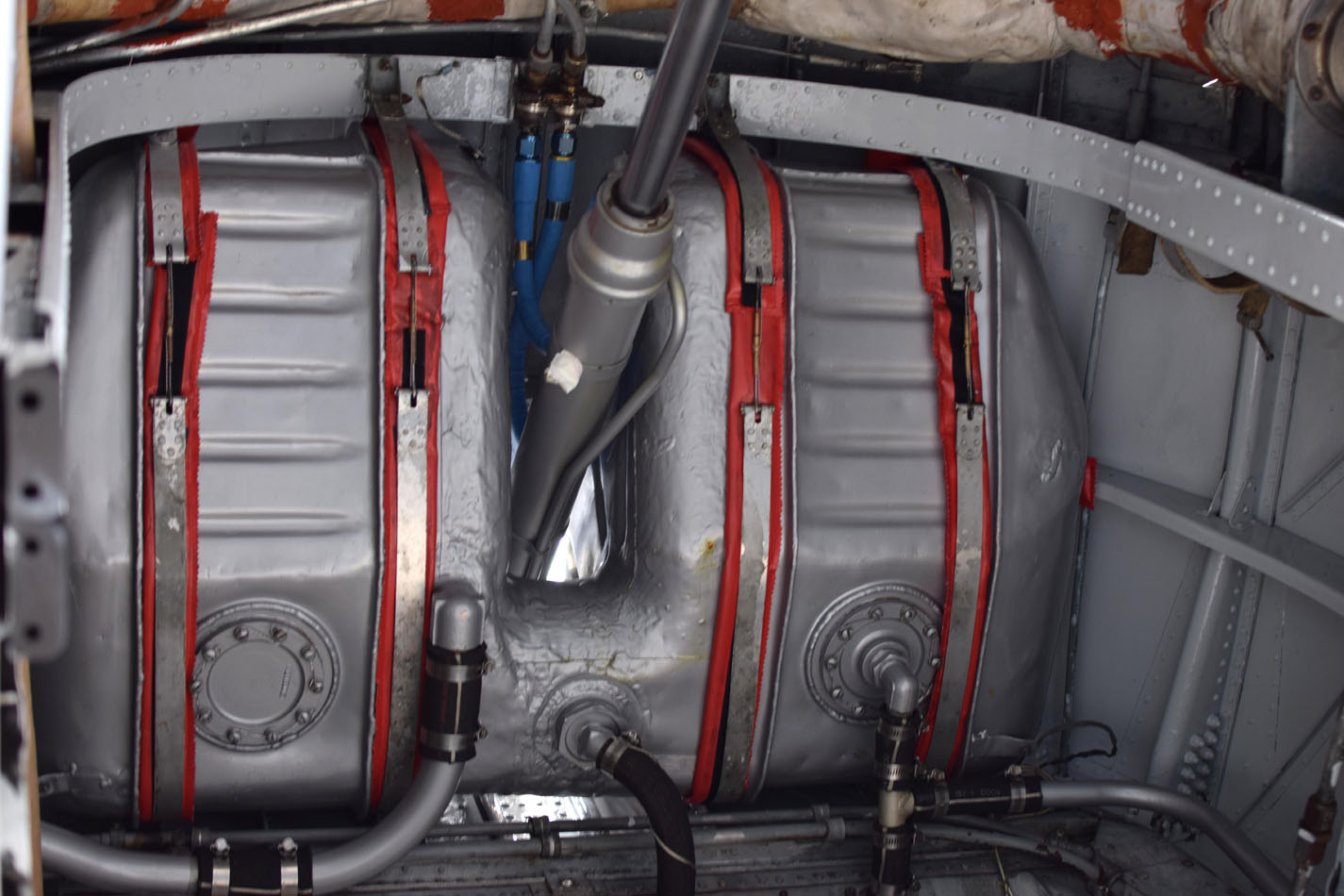

2. Oil tanks fitted and plumbed

Oil tanks have now been installed and plumbed into the system. These supply oil to the engines, and are equipped to hold 28 gallons of oil – or nearly 96 litres.

When the engines are fitted, rigorous testing will be required to ensure the functionality of the engines. Leak checks will be carried out, and will be repeated when the engines are fitted to the aircraft. Rigging checks will also be conducted for the fuel mixture control, engine throttle control and propeller control (termed as pitch control). Fuel leak checks will also be included for the entire engine assembly. These checks are very important, as a fuel leak can lead to an engine fire if the problem is not rectified.

Except for the necessary testing stage, the oil tanks can now be considered finished.

3. Landing gear actuators installed

DC3s were one of the first types of modern airliner aircraft to be fitted with retractable landing gears.

The landing gear actuators help to raise the landing gear after take-off and lower it prior to landing. A hydraulic compensator assists the main land gear with retraction. Interestingly, this function was previously achieved using a material similar to bungee cord.

4. Flight instruments installed, pitot-static check remaining

Everything is coming together in the cockpit. Flight instruments have been reinstalled following refurbishment. These include a manifold gauge for measuring air pressure inside the engine manifold, and an rpm gauge for displaying engine speed in revolutions per minute (RPM).

Reinstalling and rigging the flight controls presented the most challenging aspect of restoration effort for the month. The next big challenge facing our team is installing the engines. Stay tuned for the next update!